Corelap Layout Software

Computerized Layout Planning. » E.g., CORELAP. INEN 416 Facility Location, Layout, and Material Handling 10/9/2004 Texas A&M Industrial Engineering 9 INEN 416 124 Texas A&M Computerized Layout. COMPUTERIZED RELATIONSHIP LAYOUT PLANNING (CORELAP) The Procedure adopted for using.

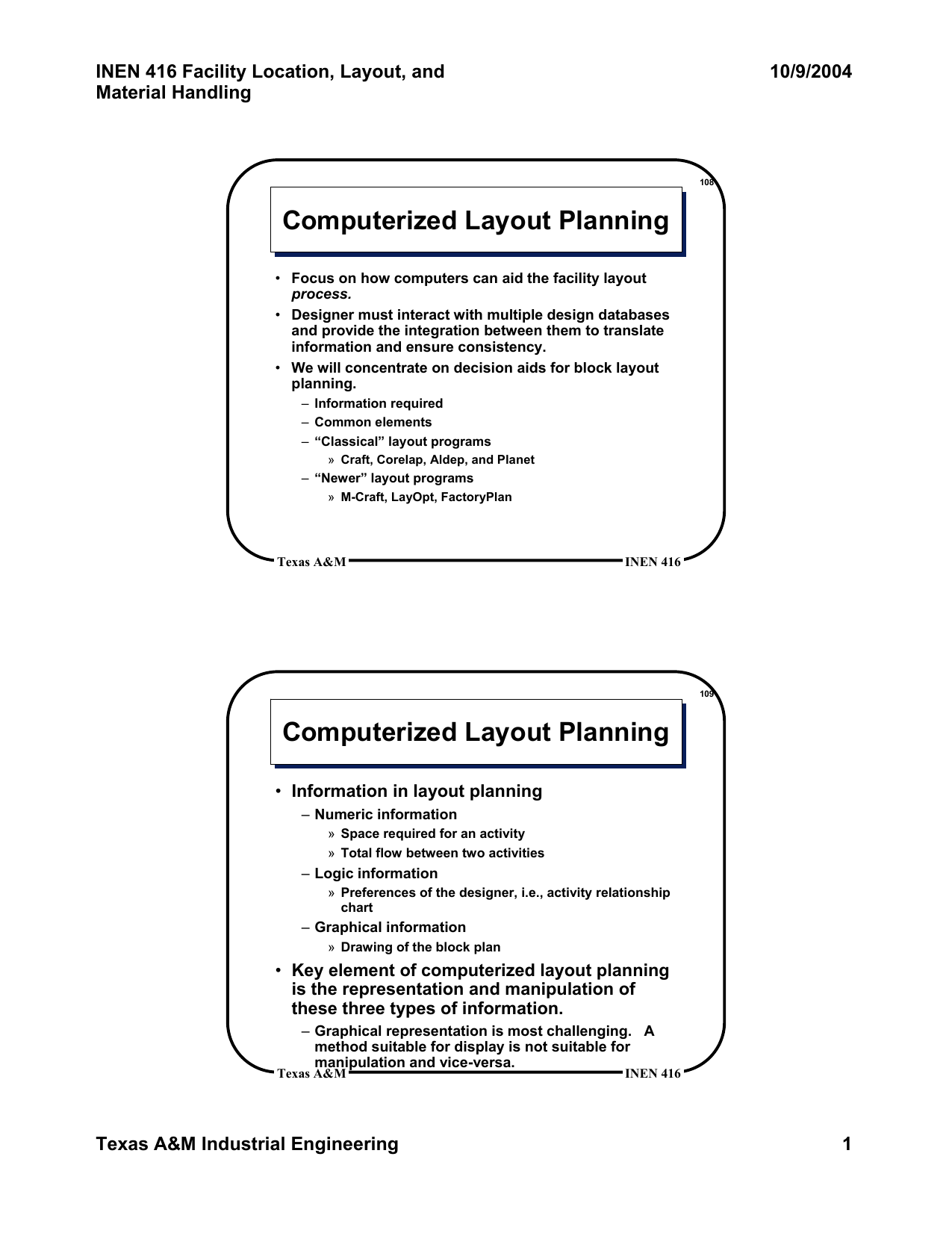

OPERATIONS MANAGEMENT ASSIGNMENT Topic: COMPUTERIZED LAYOUT ANALYSIS TECHNIQUES Submitted By: SAMYADIP CHAKRABORTY MOHD. ABDUL NAYEEM PhD Batch -2010 COMPUTERIZED LAYOUT ANALYSIS TECHNIQUES In the field of computerized layout analysis, a number of computerized layout programs have been developed since the 1960s and 70s. But the most time tested computerized layout techniques and software program packages that are frequently used are- CRAFT, CORELAP, ALDEP, etc.

Originally developed in late 60’s and early 70s, many of these packages are still around with latest additions to their features. Layout problems often involve a given number of facilities which must be located in the plane. Each of these facilities has a given area, and the cost of interactions between every facility pair is known.

Problem optimality is achieved when facilities do not overlap and the total cost, which is the sum of weighted distances between all pairs of facilities, is minimized. CRAFT (Computerized Relative Allocation of Facilities Technique) CRAFT (Computerized Relative Allocation of Facilities technique) is the most widely applied. CRAFT algorithm was originally developed by Armour and Buffa in the 1970s. It is more widely used than ALDEP and CORELAP.

It starts with an initial layout and improves the layout by interchanging the departments pair-wise so that the transportation cost is minimized. CRAFT method uses the same basic idea used for a factory layout with certain significant operational differences.

It requires a load and a distance matrix as initial inputs and also feeds in data regarding the cost involved per unit distance moved. With these inputs and an initial layout in the program, CRAFT attempts to improve the relative placement of the departments as measured by total material handling cost for the layout.

The Nexus 2 Crack Reddit Is The Next Generation'S Highest Quality Rom Synthesizer That Can Turn Your Musical Ideas Into A Stunning Reality. Forget About Stereotypical, Annoying, Stale, Old Calling Rom Synths And Embrace The Power Of Nexus2 To Evolve Your Products To A New Level Of Importance.

CRAFT is a method of “successive” improvements. CRAFT uses a pair wise exchange to develop an improved layout. It makes improvements by exchanging pairs of departments iteratively until no further cost reductions are possible.

The program calculates the effect on the total cost of exchanging departments; if this leads to a reduction, the change is made and it leads to iteration. The CRAFT requirements are: Initial layout Flow data Cost per unit distance Total number of departments Area of departments The CRAFT model represents a breakthrough in the ability to systematically evaluate layout problems having complex flow. The superiority of results obtained by earlier techniques was in no small way dependent upon the art of the layout analyst. The CRAFT model can generate and evaluate layouts having as many as 40 departments in less than one minute of computer time. In addition, any department or departments may be fixed in particular locations. The inputs to the CRAFT model are similar to those used in link analysis; travel charting and operations sequence analysis. CRAFT takes interdepartmental flow data and weights them by materials handling cost data; the result is a cost weighted flow matrix.

The only additional input is an initial block lay-out which may be the existing layout or any proposed layout. The computer determines the centroid of each department and measures the distances between centroids on rectangular coordinates. The result is a distance matrix which is multiplied by the cost weighted flow matrix to determine the materials handling cost for that particular block layout.

The governing heuristic algorithm then looks for the largest potential materials handling cost reduction obtained by switching the location of any 2 or 3 departments. The change so indicated is made, the new block diagram is printed out, and the procedure is repeated until a block diagram is produced which cannot be improved.

In theory, if a construction procedure, using a method unrelated to the pairwise exchange algorithm, can produce layouts competitive with those produced by CRAFT applied to random initial layouts, then the construction procedure followed by CRAFT should produce lower cost layouts than CRAFT alone. This technique only utilizes graphic and schematic analysis for materials flow but does present a well-organized enumeration of pertinent qualitative factors.

These factors are incorporated into a methodology for the determination of which sub-groups or departments most require adjacent placement as well as for the evaluation of several proposed layout solutions. CORELAP CORELAP is Computerized Relationship Layout Planning. This algorithm is based on Muther’s procedure given in Systematic Layout Planning. The input requirements to CORELAP are -Number of departments and their area, Closeness relationship as given by REL-chart and Weighted ratings for REL-chart entries. Working with Corelap: CORELAP (Computerized Relationship Layout Planning) is a simple method in facility layout and location discipline which is usually used to design a factory and facility. As a facility of living, house should be designed by using CORELAP method.